A complete joining unit with a simple principle. You define the element - we designe the setting equipment.

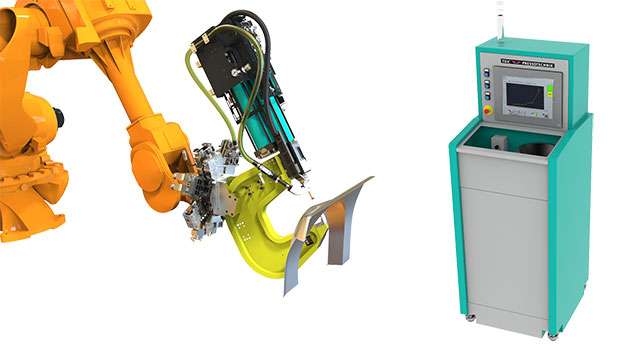

Joining possible in any direction, even upside down.

Riveting Systems

Riveting demands competetent technology

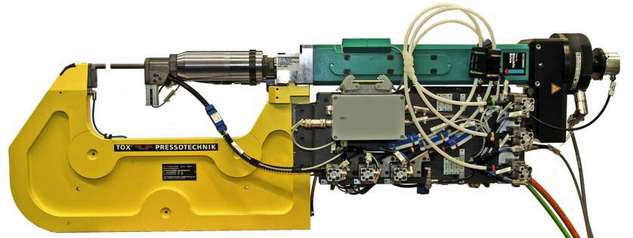

Press or tongs with TOX®-Drive

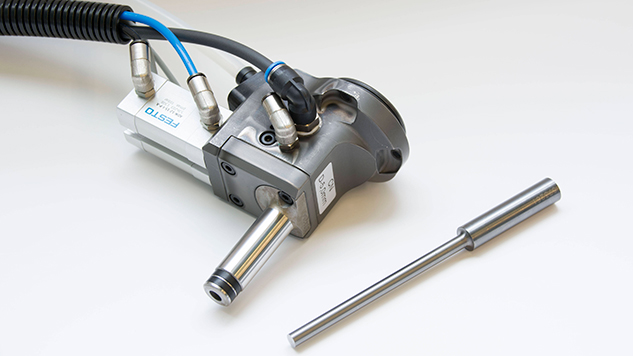

Swage head

Feed tube

Singulator

Controls for the complete press cycle

Test report

A rivet-handling system is a complex machine but our TOX® modular concept combines many standardized parts to create an efficient, customized solution. A standard Rivet-press could be for example a TOX® universal press type CEU. Brilliant simplicity: a small feeder separates the rivets, which are fed without any additional controls, positioned in the riveting head and pressed into the piece part. This can be done in an equal manner with single-point, robotic and multi-point units.

As pointed out already, the manual and the robot tongs systems mainly consist of standardized parts and subassemblies. The construction of the robot tongs is, on principle, the same but they are equipped with a coupling for the attachment to the robot. The TOX®-tongs are distinguished by an extremely torsion-resistant construction and a rugged assembly so that a reproducible joining quality can be guaranteed for the solid punch rivet process. For this purpose the most dynamical TOX®-ElectricPowerDrive EXe-L are used. The drive is equipped with force and travel transducing sensors so that the work strokes can be realized with a repetitive accuracy of +/- 0.01 mm.

For any questions you may have about our custom riveting equipment, please contact us today!

A complete joining unit with a simple principle. You define the element - we designe the setting equipment.

Joining possible in any direction, even upside down.

Using one press or tongs, various sheet metal thicknesses requiring different length rivets can be joined under optimum parameter conditions.

This is possible using a special setting head which feeds the correct rivet type into place.

The concept of TOX® PRESSOTECHNIK for optimum machine operation:

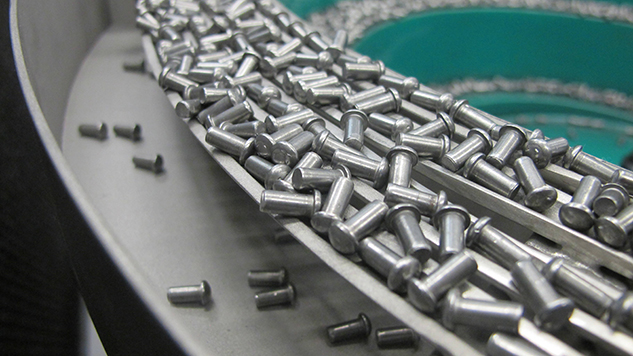

The singulator in the rivet supply module is typically located outside the robot cell and can be easily refilled at any time. The supply module provides for a fill quantity inside the magazine tube. The robotic tongs asks for a rivet when required. Modular design for quick and simple exchange of components.

The singulator in the rivet supply module is typically located outside the robot cell and can be easily refilled at any time.

A combined agitation and blowing process is enough to send the symmetrical ClinchRivet® reliably into the feeding track. The simple construction of the feeding and control units high process reliability. Sensors monitor fill levels.

For the more complicated shape of a semi-hollow rivet, we have expertise in several cases regarding the singulation of the rivet.

Contact RO: +40 268 306366 Contact form |

Cookie Information We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |