Special crossflow filters are required for the aseptic production of antibodies and vaccines. So as not having to completely clean the production equipment for the next use mechanically and chemically following product-related and thus batchwise use, the specialist for medical engineering production, Sartorius Stedim Biotech GmbH, D-37079 Göttingen, includes so-called “disposable products” like these crossflow filters in its range. The user can simply dispose of the filters after single use and only needs to perform the usual cleaning tasks, saving a lot of time and ensuring that the systems will be available again more quickly. Sartorius Stedim Biotech supplies the crossflow filters as well as associated connections and whole hose sets upon request to its customers. In order to turn the crossflow filters into practical disposable products, they must be closed hermetically, which is done through the adhesion of plates to both ends of the filter systems. The plates are therefore required to safely keep back the respective fluids, and to enclose the filter system as a complete unit. The associated adhesion process is rather difficult, as the filter systems mostly consist of pressure-sensitive silicone material. For final assembly, this requires sensitive press-in procedures on the one hand, on the other, the set press force must be applied permanently for a specified time. The silicone adhesive is only injected after the setting process of the filter system, and as soon as the adhesive has hardened, the finished product can be removed and packaged.

An individual complete solution from the TOX®-Press Modular Kit

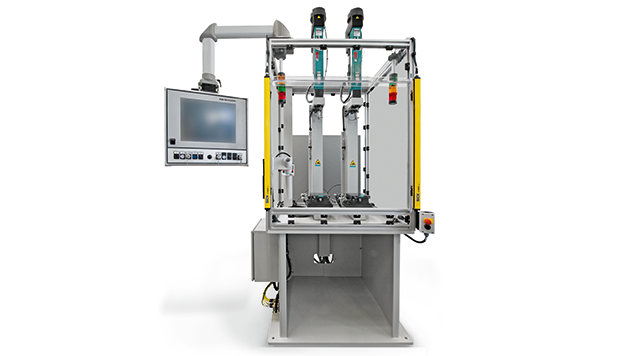

As the crossflow filters come in several sizes, which in turn require quite different press force settings and various pressing time procedures, Sartorius Stedim Biotech GmbH was looking for a suitable supplier for press systems. Those responsible for production finally found the right technology company in TOX® PRESSOTECHNIK GmbH & Co. KG, D-88250 Weingarten, which suggested a solution with a standard press system with electromechanical drive. The concept and delivery from one source were a complete winner, so that TOX® PRESSOTECHNIK received the order initially for one press system, followed by a second in due course. The two more or less identical press systems each consist of one TOX®-C-Frame Benchtop press of type CMB, a universal base frame UUM, an electromechanical press drive TOX®-Electric-Power-Module EPMK 055, a control unit STE 510 line-X as well as accessories and complete assembly ready for operation. The C-Frame Benchtop presses are designed in heavy steel plate construction and intended for press forces up to 55 kN. The C-Frame throat depth and the insertion height with 140 mm or 750 mm respectively are adapted to the maximum size of the crossflow filter cartridges to be machined with 500 x 200 x 180 mm. The presses have one ram each, which is guided highly stable mechanically and precisely by means of an antifriction bearing unit (guide rail, carriage with ball bearing unit). The presses are also equipped with a table board/mounting plate for mounting different product fixtures, and the working height is an ergonomically optimal 900 mm. A safety enclosure with safety door is attached to the front of the base frame.

High process and product flexibility with programmable press-in procedures

AOne highly dynamic electromechanical servo unit each of compact type TOX®-Electric Power Module EPMK 055 is installed as press drive. The nominal force is 55 kN, the working piston speed is 0 – 50 mm/s, the total stroke is 300 mm, and the positioning repeat accuracy is in the range of +/- 0.01 mm. The larger brakes of the Electric Power Modules EPMK 100 are integrated in the drives, with a retention force of 50 kN, in order to act as an holding brake and to achieve safety category 4. The press system is controlled, programmed and operated with the TOX®-Supply and -Control Unit STE “for servo-motor driven presses with brake with 1-hand design”. This control is a freely programmable system specifically for the servo drives TOX®-ElectricDrive for force/distance-controlled and process-monitored press force/motion sequences. Here, up to 270 different processes with more than 2,200 individual functions can be programmed and stored in the internal memory or retrieved when required. TOX® PRESSOTECHNIK supplied the press systems as complete and equipped units ready for operation, and further equipment with workpiece mount(s) and pressure plate(s) took place at Sartorius Stedim Biotech GmbH. As already indicated, the experience with the first supplied press system was so positive that a second system was commissioned after some time. This is now also being fully used, and in both cases, those responsible at Sartorius Stedim Biotech consciously backed the offer “complete delivery from one responsible source”.