To ensure high efficiency, above all the automotive industry and its suppliers rely on a high degree of automation. This in turn is based on reproducibly precise component and assembly quality, so that mounting and joining processes can be performed smoothly. However, for this purpose, technical (production-related) and not least functional and finally optical aspects must be considered here. If this concerns the attachment of doors and lids on the body, or the installation of closing mechanisms on said doors and lids etc., calotte embossing is the technology of choice. In calotte embossing, precise indentations are stamped onto one or more sheets of metal, which are used to hold the respective fastening screws. The calottes simplify assembly on the one hand with a type of pre-centering, on the other hand, these indentations ensure that the fastening screws do not protrude and do not form any or only slight interfering edges. Strictly speaking, calotte embossing is a combination of both procedures punching and forming/stamping, by firstly punching out the mounting holes and then forming the indentations. Consequently, tools (punch and die) are required for this, as well as mechanical devices with press force drive. Ideally, both procedures of punching and forming are combined in one tool, as one work step can be saved this way and the calotte embossing is completely alligned with the hole.

Individual calotte embossing solutions from a standard modular system

Now the technology company TOX® PRESSOTECHNIK GmbH & Co. KG from 88250 Weingarten in Germany comes into play. Its range of products and services includes technologies and procedures for mechanical sheet metal forming as well as mechanical engineering equipment and drive technology to realize the respective production facilities. Punching, forming, joining sheet metals and the tools required for this on the one hand, presses, C-frames, robot/machine tongs including controls and software or defined interfaces on the other hand - with these, TOX® PRESSOTECHNIK is one of the few companies able to provide individual and at the same time reasonable system solutions for punching and calotte embossing based on the standard modular system. An impressive example for this system solution competence is the development, the construction and supply of two tongs systems, with which 3 calottes are to be embossed each on the left or right sliding doors of a pickup truck's loading space. The big advantage here is that first of all, two sheets of metal are punched and fixed with only one working stroke in three positions, and three calottes are embossed with the geometry D = 6.3 mm x 90°.

Subsystem ready to dock without interface issues

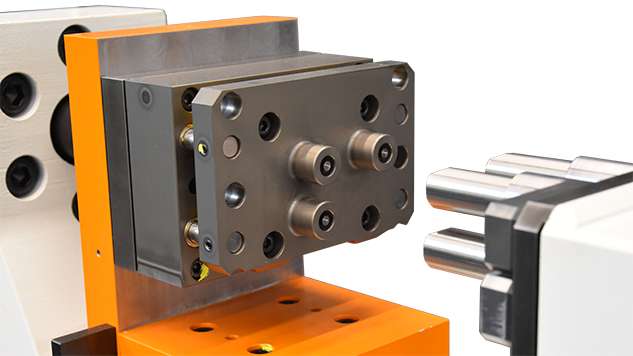

The two TOX®-Punching Tongs of type SMB are designed and installed as single stations and are based on C-frames with larger, in other words adjusted throat depth and for press forces up to max. 300 kN. A pneumohydraulic cylinder of type TOX®-Powerpackage X-S 030 is used as a drive, the tool consists of three combined stamping/forming punches and three stamping/forming dies, a linear guide system for the tool system and a holding-down device. Furthermore, the scope of delivery comprises position sensors for top/bottom dead centre (TDC/BDC), an adapter plate for attaching the punching tongs to stands or mounting brackets provided by the customer. Additionally a compensating slide at the rear of the C-frame with stroke 10 mm and driven by pneumatic cylinder, and finally the external pulse control STE for controlling the complete punching system and as interface for the plant control. The tongs for combined and simultaneous punching and embossing of three calottes each were supplied by TOX® PRESSOTECHNIK as workstations directly ready for docking. The customer thus received a complete package from a single source and did not need to worry about the interfaces, neither concerning the punching/embossing technology nor machine and tool building.